This test is done for Road Bridges. A CYCLE of load by placing loaded vehicles/Concrete blocks in approved positions in sequence as per Bridge codes IRC: SP: 51, IRC: SP: 37 & IRC: 6 – 2010 and maintained for 24 HRS . Then unloading is done in same sequence. In both sequence of loading the deflection readings are taken as . MOREOVER we OBSERVE the WIDENING OF FLEXURAL CRACKS (ANY NEW CRACKS AND WIDENING OF THE EXISTING ONES) AT EVERY STAGE OF LOADING, SO AS TO DECIDE ABOUT PLACEMENT OF NEXT INCREMENTAL LOAD. IT HAS EXPECTED THAT THE LOAD-DEFLECTION CHARACTERISTICS AT EVERY INCREMENT ARE LINEAR AND ANY ABNORMAL BEHAVIOR WAS NOT REFLECTED IN THE LOAD –DEFLECTION DATA.

THE METHODOLOGY ADOPTED FOR BRIDGE LOAD TEST IS IN SUCH A WAY THAT THE STATIC LOAD BE PRODUCED ON SELECTED SPAN BY BUILDING UP PRE WEIGHED TRUCKS ARRANGE ABOVE POSITIONED MARKED(AS perprescribed bridge codes mentioned above). THE AREA OF PLATFORM DECIDED AS PER MAGNITUDE OF THE IRC CLASS LOADING.

In a project the construction of Major Bridge is completed in accordance with the approved drawings. It is customary to evaluate the performance of these bridges prior to opening/run the train onto these bridges. In view of this it is needed to evaluate the performance of OWG/Composite Girder/PSC Slabs/Plate Girder bridges by conducting “Deflection Test” as per the guidelines laid down in BS-128, IRS Concrete Bridge Code- 25t Loading standard-2008 and IRC: SP: 51: 2015 using calibrated sensors.

To check the dynamic effect of a rail bridge a Diesel engines /Power with loaded wagons are allowed to pass at a constant speed ie at a sectional speed allowed by rail authority over the bridge. We will record the displacement of test span . For measurement of dynamic effect we place (LVDT SENSORS of 0.01mm sensitivity) below two girders at mid points of EACH span resting over rigid staging by means of magnetic stand (below both girder) over bed level..

This test is done to check load capacity of a concrete PSC slab/Composite girder rail bridges as per pre-calculated load along with pre-calculated deflection (calculation is done as per IS CODES & Drawings). We apply load by using rail sleepers/concrete blocks on test span and fixing sensors to see the deflection due to load applied on bridge slab beneath the test slab/girders at different points.

Confirm the design load calculations and to provide guidelines for setting up the limits of acceptance for routine tests.

Batter piles either individually or in groups to determine the load-deflection relationship when subjected to lateral loading.

Determine the ultimate bearing capacity of the soil and the probable settlement under a given loading.

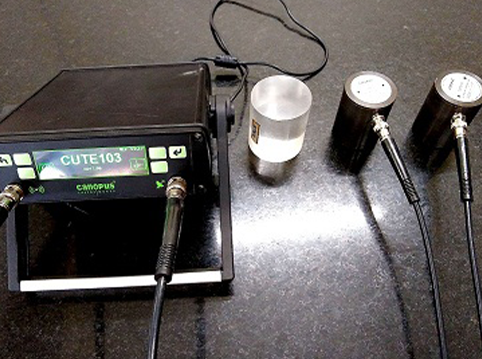

This test is done to assess the quality of concrete by ultrasonic pulse velocity method as per IS: 13311 (Part 1) - 1992. The underlying principle of this test is - The method consists of measuring the time of travel of an ultrasonic pulse passing through the concrete being tested.

Rebound hammer is used for compressive strength of concrete (as per IS-13311(Part-2)/92). Rebound hammer consists of a spring-loaded steel hammer that when released strikes a steel plunger in contact with the concrete surface.

Structural steel fabrication is a process of bending, cutting, and molding steel structures to create beams, columns, and steel members. Structural steel fabricators erect and provide quality, fabricated steel components and structures. Structural steel is cost effective, durable, and highly stable for construction.